Deliver value through cost-effective steel solutions

Best Practices for Maintaining Rectangular Hollow Section Steel Structures

Jul 08,2025

Best Practices for Maintaining Rectangular Hollow Section Steel Structures Table of Contents 1. Introduction to Rectangular Hollow Section Steel Structures 2. Importance of Maintaining RHS Steel Structures 3. Common Issues Faced by RHS Steel Structures 4. Preventive Maintenance Measures 4.1 Corrosion Protection Strategies 4.2 Coating Applications and Maintenance 5.

Best Practices for Maintaining Rectangular Hollow Section Steel Structures

Table of Contents

- 1. Introduction to Rectangular Hollow Section Steel Structures

- 2. Importance of Maintaining RHS Steel Structures

- 3. Common Issues Faced by RHS Steel Structures

- 4. Preventive Maintenance Measures

- 5. Routine Inspections and Testing

- 6. Repair Techniques for RHS Structures

- 7. Case Studies: Successful Maintenance of RHS Structures

- 8. Frequently Asked Questions

- 9. Conclusion

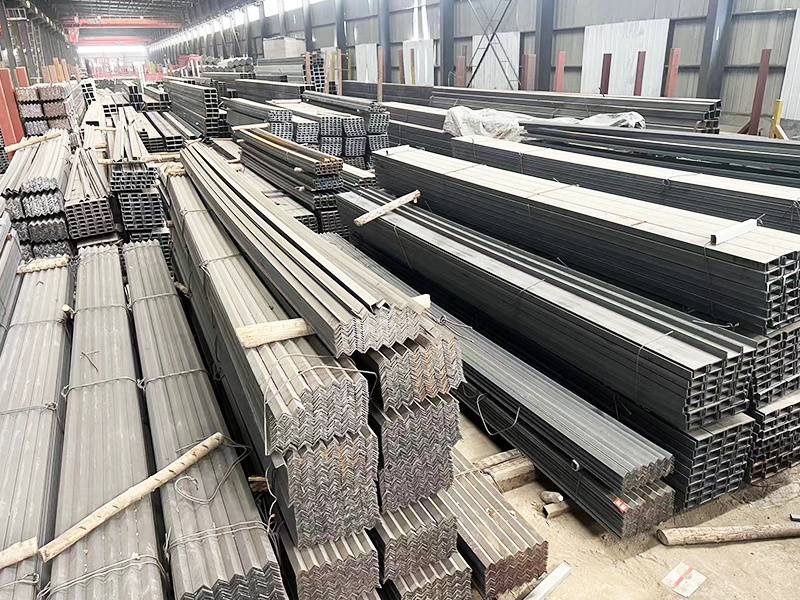

1. Introduction to Rectangular Hollow Section Steel Structures

Rectangular Hollow Section (RHS) steel structures are integral components in modern construction, serving as vital structural elements in various applications, from bridges to buildings. Their unique shape offers excellent strength and rigidity, making them ideal for structural frames, supports, and facades. Understanding how to properly maintain these structures is crucial for ensuring their longevity and performance over time.

2. Importance of Maintaining RHS Steel Structures

The maintenance of RHS steel structures is not merely a recommendation but a necessity. Regular maintenance practices are essential for several reasons:

1. **Structural Integrity**: Maintaining RHS structures ensures they remain safe and stable under load conditions.

2. **Longevity**: Well-maintained structures have an extended lifespan, reducing the need for replacements and saving costs in the long run.

3. **Safety**: Regular inspections help identify potential hazards early, thus preventing accidents and ensuring the safety of personnel and the public.

4. **Regulatory Compliance**: Adhering to maintenance practices ensures compliance with local regulations and building codes, which can vary by region.

3. Common Issues Faced by RHS Steel Structures

There are several common issues that can arise in RHS steel structures:

- **Corrosion**: Exposure to moisture and environmental elements can lead to rust and deterioration of the steel.

- **Fatigue Cracks**: Continuous loading and unloading cycles can cause fatigue, leading to cracks in the material.

- **Deformation**: Overloading or improper design can cause deformation, affecting the overall structural integrity.

- **Welding Defects**: Poor welding practices can result in weak joints, making the structure vulnerable to failure.

Recognizing these issues is the first step toward implementing effective maintenance strategies.

4. Preventive Maintenance Measures

Preventive maintenance is critical in safeguarding the integrity and durability of RHS steel structures. Implementing effective strategies can significantly mitigate common issues.

4.1 Corrosion Protection Strategies

Corrosion is one of the most significant threats to RHS steel structures. Here are effective corrosion protection strategies:

- **Galvanization**: Coating the steel with zinc offers superior corrosion resistance. This method is especially beneficial for structures exposed to harsh environments.

- **Corrosion-Resistant Alloys**: Using alloys designed to resist corrosion can be a proactive measure during the selection of materials.

- **Regular Cleaning**: Ensuring that surfaces are free from dirt and contaminants can prevent moisture retention, which contributes to corrosion.

4.2 Coating Applications and Maintenance

Proper application and maintenance of protective coatings play a vital role in preserving RHS structures. Key practices include:

- **Surface Preparation**: Ensure surfaces are clean and properly prepared before applying any coating. This involves removing rust, dirt, and old paint.

- **Quality Coatings**: Use high-quality, weather-resistant paint or varnish specifically designed for steel surfaces.

- **Regular Reapplication**: Schedule periodic inspections to determine when new coatings are necessary to maintain protection levels.

5. Routine Inspections and Testing

Routine inspections are crucial in identifying potential issues before they escalate into costly repairs. Regular testing ensures the ongoing safety and performance of RHS structures.

5.1 Visual Inspections

Conducting visual inspections involves looking for visible signs of wear, corrosion, or damage. Key components to examine include:

- **Connections and Joints**: Inspect welds and joints for signs of fatigue or cracking.

- **Surface Condition**: Look for rust spots, paint peeling, or discoloration.

- **Alignment and Deformation**: Ensure that the structure remains aligned and free from any noticeable deformation.

5.2 Nondestructive Testing Methods

Nondestructive testing (NDT) methods allow for a thorough examination of RHS steel structures without causing damage. Effective NDT techniques include:

- **Ultrasonic Testing**: This technique uses high-frequency sound waves to detect internal flaws and measure the thickness of materials.

- **Magnetic Particle Testing**: Ideal for detecting surface and near-surface discontinuities in ferromagnetic materials.

- **Radiographic Testing**: Utilizes X-rays or gamma rays to view the internal structure of welds and materials.

6. Repair Techniques for RHS Structures

When damage is identified, timely repair is essential to restore the integrity of RHS structures.

6.1 Welding Repair Techniques

Welding is a common method used for repairing RHS structures. Best practices include:

- **Proper Preparation**: Clean the area to be welded, removing all contaminants that may weaken the joint.

- **Qualified Personnel**: Ensure that repairs are carried out by certified welders familiar with the specific materials and techniques required.

- **Post-Weld Inspection**: Conduct thorough inspections after repairs to ensure that the welds meet safety standards.

6.2 Replacement of Damaged Sections

In cases where sections are severely damaged, replacement may be the best option. Key considerations include:

- **Material Match**: Use materials that match the original specifications to maintain overall structural integrity.

- **Professional Installation**: Engage qualified contractors to ensure that replacements are properly installed.

7. Case Studies: Successful Maintenance of RHS Structures

Several projects demonstrate effective maintenance practices for RHS structures:

- **Case Study 1 - Bridge Maintenance**: A major city implemented routine inspections and rust prevention measures on its steel bridges, leading to a 15% increase in the lifespan of the structures.

- **Case Study 2 - High-Rise Building**: An office tower underwent a comprehensive maintenance program, including coating applications and NDT, which significantly reduced the incidence of structural failures.

These examples illustrate the benefits of proactive maintenance strategies.

8. Frequently Asked Questions

What is a rectangular hollow section (RHS)?

A rectangular hollow section (RHS) is a type of structural steel shape characterized by its rectangular cross-section. It is widely used for construction due to its strength and versatility.

How often should RHS steel structures be inspected?

It is recommended to conduct visual inspections at least annually, with more frequent inspections in harsh environments or following severe weather events.

What are the signs of corrosion on RHS structures?

Signs of corrosion include rust formation, flaking paint, and discoloration of the steel surface. Early detection is crucial for effective maintenance.

Can corrosion be prevented in RHS structures?

Yes, effective corrosion prevention measures include galvanization, regular cleaning, and the application of protective coatings.

What should I do if I find a crack in an RHS structure?

If a crack is discovered, it is essential to consult a structural engineer immediately for assessment and potential repair options.

9. Conclusion

Maintaining Rectangular Hollow Section steel structures is a vital aspect of ensuring their longevity and structural integrity. Through regular inspections, proactive maintenance strategies, and timely repairs, we can prevent costly damages and ensure the safety of our built environments. By following the best practices outlined in this guide, professionals in the construction and engineering industries can greatly enhance the performance and durability of RHS structures, leading to safer and more sustainable infrastructure.

Prev:

Releated News

Contact Info.

E-mail:

info@zthtsteel.com

Phone:

+86-18500313801

Whatsapp:

8618526720427

Fax:

+862268569909

Mailing Address:

Room 903, Block B, Haitai Xinxi Square, Hua Yuan Industrial Area,Tianjin,China. Zip code: 300384