Deliver value through cost-effective steel solutions

How Slotted Angle Steel Can Transform Your Building Structures

Jun 06,2025

How Slotted Angle Steel Can Transform Your Building Structures Table of Contents 1. Introduction to Slotted Angle Steel 2. What is Slotted Angle Steel? 3. Applications of Slotted Angle Steel in Construction 4. Advantages of Using Slotted Angle Steel 5. Design Flexibility with Slotted Angle Steel 6. Installation Process of Slotted Angle Steel 7. Case Studies: Successful

How Slotted Angle Steel Can Transform Your Building Structures

Table of Contents

- 1. Introduction to Slotted Angle Steel

- 2. What is Slotted Angle Steel?

- 3. Applications of Slotted Angle Steel in Construction

- 4. Advantages of Using Slotted Angle Steel

- 5. Design Flexibility with Slotted Angle Steel

- 6. Installation Process of Slotted Angle Steel

- 7. Case Studies: Successful Implementations

- 8. The Future of Slotted Angle Steel in Construction

- 9. FAQs about Slotted Angle Steel

- 10. Conclusion

1. Introduction to Slotted Angle Steel

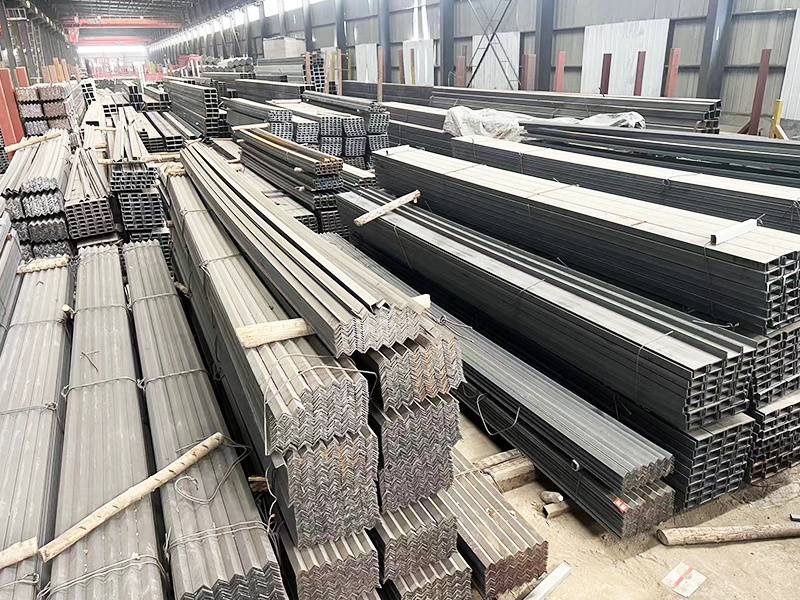

In the realm of construction and building materials, **slotted angle steel** has emerged as a transformative element. Known for its versatility and strength, this material serves as a backbone for various structural applications. As we delve into the ins and outs of slotted angle steel, we will explore its innovative uses, standout advantages, and how it can revolutionize your building projects.

2. What is Slotted Angle Steel?

Slotted angle steel refers to a type of structural steel that comes in the form of **L-shaped angles** with pre-drilled slots. These slots allow for easy adjustment and connection with other structural components, making slotted angle steel an ideal choice for various construction needs. This material is typically manufactured from high-quality steel and can be galvanized for enhanced durability.

Key Features of Slotted Angle Steel

- **Adjustability:** The pre-drilled slots enable quick and precise adjustments during assembly.

- **Strength:** Despite its lightweight nature, slotted angle steel is robust and can support significant loads.

- **Corrosion Resistance:** Galvanized options provide protection against rust and deterioration.

3. Applications of Slotted Angle Steel in Construction

The versatility of slotted angle steel makes it suitable for a wide range of applications in construction. Here are some notable uses:

3.1 Framing Systems

Slotted angle steel is extensively used in framing systems for buildings and warehouses. Its adjustable nature allows for quick reconfiguration as needs change.

3.2 Shelving Units

This material is perfect for constructing shelving units in commercial and industrial settings. Its ability to support heavy loads while maintaining stability makes it a preferred choice for storage solutions.

3.3 Supports for Equipment

Slotted angle steel is often utilized as support structures for various equipment, such as HVAC systems and piping. Its strength and adjustability ensure optimal installation and functionality.

4. Advantages of Using Slotted Angle Steel

Choosing slotted angle steel for your construction projects comes with numerous benefits, including:

4.1 Cost-Effectiveness

The adjustable nature of slotted angle steel often leads to reduced labor costs. Less time spent on installation translates to savings on overall project expenses.

4.2 Ease of Installation

With pre-drilled slots, slotted angle steel can be assembled quickly and easily. This simplicity reduces construction time and minimizes the likelihood of errors.

4.3 Versatile Design Options

Slotted angle steel can be cut and shaped to meet specific design needs, allowing architects and engineers to unleash their creativity without compromising structural integrity.

5. Design Flexibility with Slotted Angle Steel

In modern architecture, design flexibility is paramount. Slotted angle steel provides endless possibilities, enabling designers to create complex structures that are both functional and aesthetically pleasing.

5.1 Customizable Configurations

The ability to adjust and reconfigure slotted angle steel components allows for tailored designs that meet precise specifications. This is particularly advantageous in unique architectural projects.

5.2 Integration with Other Materials

Slotted angle steel can be seamlessly integrated with other building materials, such as wood and concrete. This compatibility opens the door to hybrid designs that maximize both visual appeal and structural performance.

6. Installation Process of Slotted Angle Steel

Installing slotted angle steel is straightforward, ensuring that projects proceed without unnecessary delays. Here’s a brief overview of the installation process:

6.1 Preparation

Before installation, it's crucial to assess the building site and determine the specifications for the slotted angle steel components.

6.2 Cutting and Shaping

Using appropriate tools, slotted angle steel can be cut to the desired lengths and angles, ensuring a perfect fit for the project.

6.3 Assembly

The assembly process involves connecting the slotted angle steel pieces using bolts and nuts, taking advantage of the pre-drilled slots for precise alignment.

6.4 Final Inspection

After installation, a thorough inspection is performed to ensure all connections are secure and that the structure meets safety standards.

7. Case Studies: Successful Implementations

To showcase the efficacy of slotted angle steel, let’s examine a couple of successful implementations:

7.1 Industrial Warehouse Project

In a recent industrial warehouse project, builders opted for slotted angle steel to create an efficient shelving system. The result was a flexible storage solution that significantly improved space utilization and reduced operational costs.

7.2 Office Building Renovation

During a renovation of an office building, slotted angle steel was used to redesign the internal framework. This allowed for open office layouts, enhancing collaboration while maintaining structural integrity.

8. The Future of Slotted Angle Steel in Construction

As the construction industry continues to evolve, slotted angle steel is poised for further innovations. Advancements in manufacturing processes and materials science will likely enhance its functionality and applications.

8.1 Sustainable Practices

With growing emphasis on sustainability, the use of slotted angle steel is expected to rise as it can be easily recycled and reused, aligning with eco-friendly building practices.

8.2 Technological Integration

The integration of smart technologies into construction processes will further optimize the use of slotted angle steel, allowing for real-time adjustments and enhanced structural performance.

9. FAQs about Slotted Angle Steel

9.1 What is the Load Capacity of Slotted Angle Steel?

The load capacity of slotted angle steel varies depending on its dimensions and the specific application. Generally, it can support significant weights, making it ideal for various construction needs.

9.2 Can Slotted Angle Steel Be Used Outdoors?

Yes, slotted angle steel can be used outdoors, especially when galvanized for corrosion resistance. Proper coatings can further enhance its durability in harsh weather conditions.

9.3 Is Slotted Angle Steel Easy to Modify?

Absolutely! One of the key advantages of slotted angle steel is its ease of modification. It can be cut, shaped, and reconfigured without compromising structural integrity.

9.4 How Does Slotted Angle Steel Compare to Other Steel Types?

Slotted angle steel offers a unique combination of strength, adjustability, and cost-effectiveness that sets it apart from other steel types, making it a favored choice in many applications.

9.5 Where Can I Purchase Slotted Angle Steel?

Slotted angle steel can be purchased from various suppliers, including hardware stores and specialty construction material retailers. It's advisable to ensure the steel meets industry standards.

10. Conclusion

In summary, slotted angle steel serves as a game-changing component in modern construction. Its versatility, strength, and ease of installation make it an invaluable asset for architects, engineers, and builders alike. As we continue to explore innovative building materials, slotted angle steel stands out as a solution that not only enhances structural integrity but also promotes design flexibility and cost efficiency. Embracing this material can lead to a future of construction that is not only functional but also inspired by creativity and sustainability.

Next:

Releated News

Contact Info.

E-mail:

info@zthtsteel.com

Phone:

+86-18500313801

Whatsapp:

8618526720427

Fax:

+862268569909

Mailing Address:

Room 903, Block B, Haitai Xinxi Square, Hua Yuan Industrial Area,Tianjin,China. Zip code: 300384